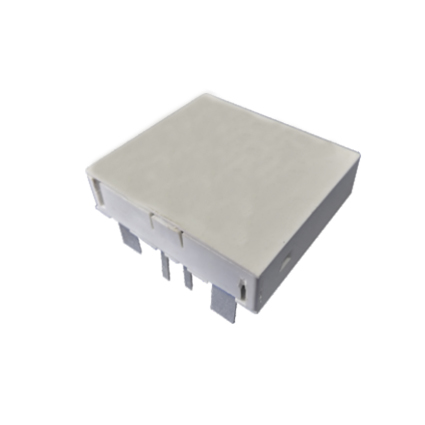

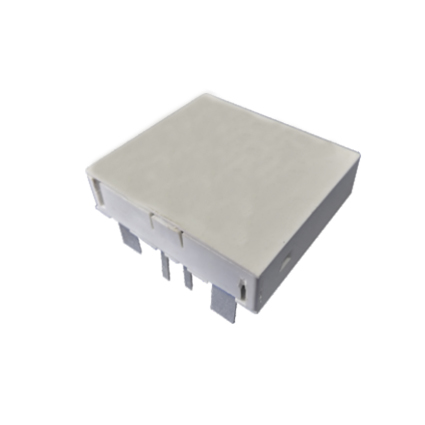

The core technical advantage of the TRB20K31 series of onboard SPD products lies in the use of our company's top-level MOV chip with controllable melt-through point. The power-frequency current melt-through point is completely controlled in the center area of the chip, and the thermal detachment low-temperature solder point is designed on the protruding copper sheet in the middle. , Under the protruding copper sheet, a metal refractory sheet from the melting point is used, which is difficult to be melted by the molten fluid in a short time. Smooth movement tripping is used to increase tripping distance, eliminate the possibility of arcing, improve reliability and save space. This structure is only applicable to the MOV produced by our company with a melting point within a radius of 0.5cm from the center. If the MOV penetration point is not in the central area, the effect will be significantly reduced.

This solution will be used for reliable miniaturized SPD (module thickness 12mm) design. According to this feature, the thermal detachment mechanism is optimized to make the heat conduction speed the fastest and the thermal detachment efficiency is excellent.